Thermo Fisher Scientific:

Various Projects

Developing new tools to speed up and simplify protein science.

The Challenge

Successfully launch protein science products within an organization new to both physical or digital products before.My Role

Client-facing design consultant for PDT, working with various levels of stakeholders and subject matter experts.Thermo Fisher Scientific is a massive science tech organization. Their core business supports protein science, focusing on general experiments that protein labs run frequently. I worked with them for several years to develop products supporting the Western Blot—the most common protein science experiment that determines the molecular weight, and quantity of proteins, in a compound.

The customer experience was a knotty problem. The experiment in question hadn’t changed in decades and needed a digital rethink. We aimed to launch some test products to make specific procedures easier and more connected. We identified three areas where a better product could help. There are numerous significant steps in the Western Blot process; We focused on three where we felt improvements would have an impact in establishing an ecosystem.

Project 1

Pierce Power Station: A small device that transfers a wet experiment gel to film. This replaced another container device while removed the need for a separate power supply product.

Pierce Power Station: A small device that transfers a wet experiment gel to film. This replaced another container device while removed the need for a separate power supply product.

Project 2

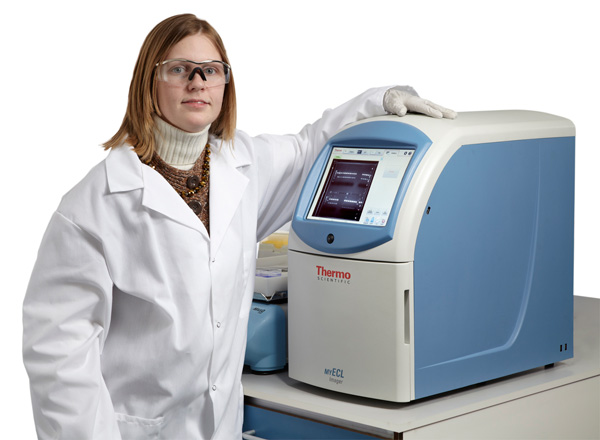

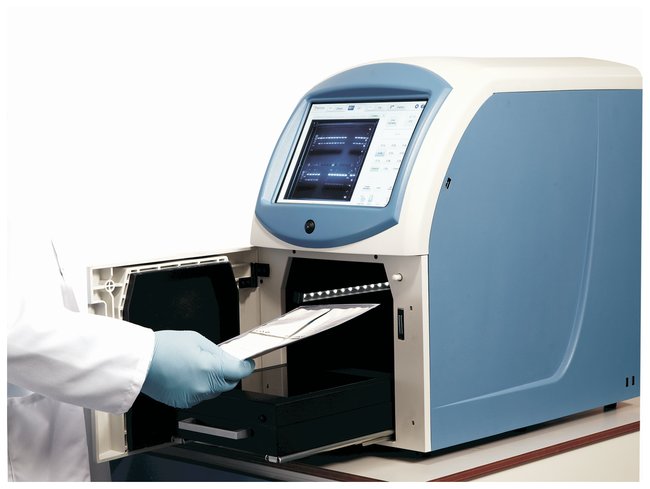

myECL Imager: A countertop kiosk that captures an image of the film from the previous step. Both of these physical products were designed to be used as communal devices within the lab, while still allowing lab workers the ability to save and customize their work and methods.

myECL Imager: A countertop kiosk that captures an image of the film from the previous step. Both of these physical products were designed to be used as communal devices within the lab, while still allowing lab workers the ability to save and customize their work and methods.

Project 3

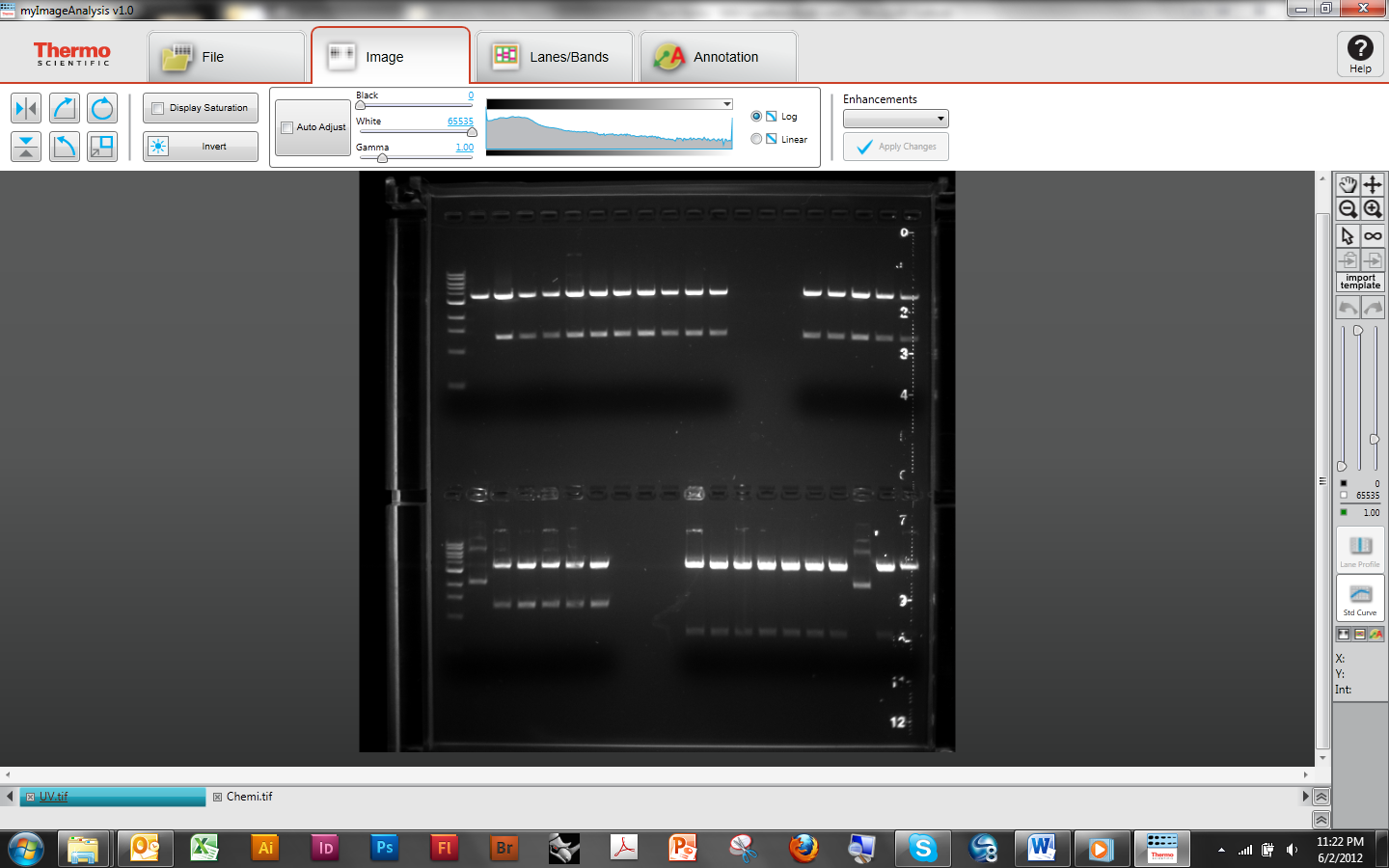

myImageAnalsis: PC software that converts the image into data for analysis. The white blots in this image are the experiment data. The software allowed for the art of manual analysis, while also providing machine-vision assisted automation.

myImageAnalsis: PC software that converts the image into data for analysis. The white blots in this image are the experiment data. The software allowed for the art of manual analysis, while also providing machine-vision assisted automation.

I worked iteratively on the screens for these products. Since I was learning how the science worked while I was exploring designs, I made heavy use of the client subject matter experts. When I had a new version of a design, I talked it through with the client. I corrected my work until it was accurate and usable, then worked with developers to see the vision implemented.

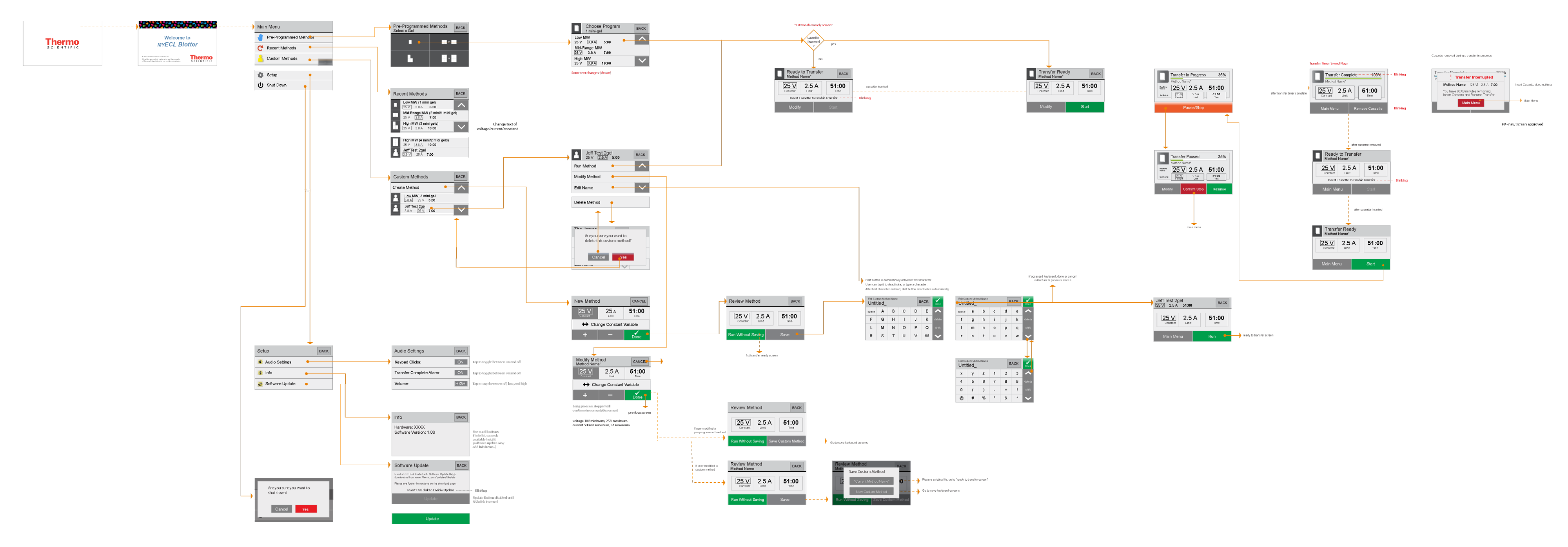

Screen architecture of the power station.

Screen architecture of the power station. With these projects underway, it was time to rethink the lab. We kicked off a large discovery project, traveling far and wide. We conducted a great deal of field research in protein science labs across the US, in addition to time working in the client’s test lab in Rockford and partner labs in Chicago. These visits provided opportunities to see lab work done in the real world and to observe the environmental and cultural factors that make labs different from each other.

A product conceptualization phase followed the field efforts. We were using generative research to plot a course for the future. The design team (chiefly the industrial designer and myself) worked in a war room, generating numerous ideas for navigating the problem space and creating competitive products. These sketches coalesced into themes, each an area for future product exploration.

Product concept sketches: all-in-one devices and consumable experiments. I designed the content of the screens, while collaborating with and loosely directing an industrial designer.

A concept that replaces a complex screen interaction with a simpler one that would connect directly to an experiment vessel.

A concept that replaces a complex screen interaction with a simpler one that would connect directly to an experiment vessel.Outcomes

1. A new product ecosystem was built. Successful launches of the three pilot products established Thermo’s presence to support the general market with quality, easy-to-maser tools.

2. Future possibilities were explored enough to predict larger industry movements. The discovery effort helped Thermo see the lab science marketplace through its customer’s eyes. My team helped them took notice of high-end labs making capital investments in innovative new products and abandoning the standard experiment model. Thermo has since initiated an aggressive strategy to acquire many relevant competitors in parallel with their own innovation efforts.